What are Industrial Minerals?

Nature’s most popular raw materials

Society uses industrial minerals, either in a processed or natural state, to make building materials, ceramics, detergents, electronics, filtration, glass, medications and medical devices, paints, paper and plastics, and many more industrial and domestic products.

So what are they? Industrial minerals are defined as minerals that are not sources of metals, fuel, or gemstones. The most widely-used industrial minerals include, bentonite, calcium carbonate, clays, diatomite, dolomite, kaolin, limestone, silica and talc.

Industrial minerals are incredibly versatile; most have at least two, sometimes many more, applications and span multiple markets.

Key facts and figures

250

member companies

685

mines and quarries

750

processing plants

42,500 people

employed in 28 European countries (30 million jobs in downstream industries)

€14 billion

contribution to the European economy

180 million

tonnes of minerals produced per year

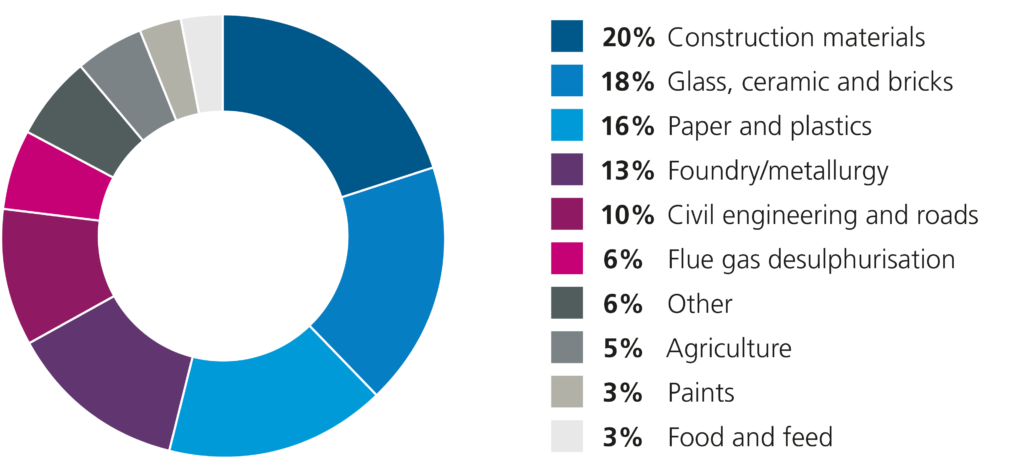

Main markets for industrial minerals in Europe

Industrial minerals are also increasingly essential to high-tech sectors through the production of wiring and fibre-optic cables, as well as environmentally friendly products and technologies such as wind turbines and photovoltaic panels.

Applications

Smartphones

contain up to 60% minerals:

- cover – calcium carbonate, mica and talc

- battery – calcium carbonate, silica and clays

- reinforced steel – silica, andalusite and lime

- glass – 47g of silica sand

Glass

contains up to 100% minerals:

- silica

- dolomite

- calcium carbonate

- lime

- feldspar

- borates

Paper

contains up to 50% minerals:

- calcium carbonate

- talc

- kaolin

- bentonite

Paint

contains up to 50% minerals:

- calcium carbonate

- quartz

- cristobalite

- plastic clays

- talc

- bentonite

- diatomite

- mica

- wollastonite

Ceramics

contain up to 100% minerals:

- feldspar

- clay

- kaolin

- lime

- talc

- silica

Houses

contain up to 150 tonnes of minerals

Cars

contain up to 150kg of minerals

Solar cells

contain up to

95% minerals

Turbine blades

contain up to

95% minerals

Iron making requires bentonite, lime and limestone